High quality condensing appliances on the European Union standards manufactured with 100% domestic capital and domestic design in Turkey.

If longer service life is expected from a high efficiency machine, it is essential to have a stainless exchanger. Stainless exchangers are more resilient compared to aluminum exchangers while offering high efficiency.

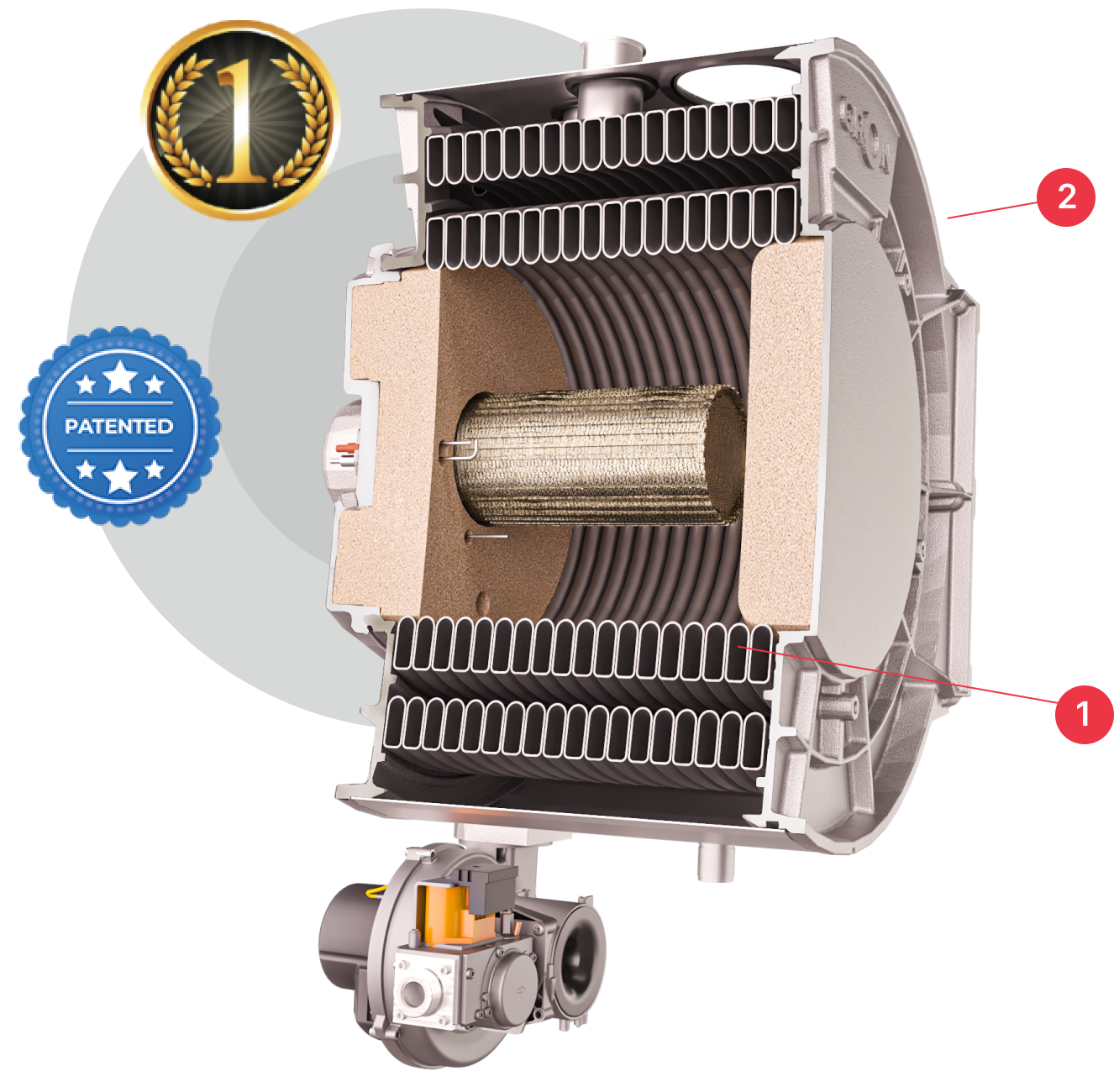

A patented original exchanger design by Turkish engineers.

Wall type stainless exchanger approved by Internationally Accredited Laboratories.

Your appliance is under 3 year warranty from the date of purchase on the terms of warranty.

When you buy your appliance with the product kit, your appliance is under 5 year warranty on the terms of warranty. (As described on Page 9, the product kit includes all mounting and installation components.)

Our appliances provide efficiency up to 109.96% as approved by internationally accredited laboratories within the normal operating range, while up to 106.2% as the leading efficiency in the sector while operating at the maximum power.

The product’s NOx class is 6 so it has low carbon emission.

15 boilers and up to maximum 2250kW central system heating power can be reached.

Accurate and easy mounting thanks to the stand, piping kit and installation kit specially designed by our company. (Page 9)

CE Certified product approved by International Italian IMQ certification organization.

According to the ErP Regulation, 92% seasonal space heating energy efficiency and grade A (A+ → D) heating efficiency.

| X 130 | X 150 | |

|---|---|---|

| Nominal Heat Power (50/30 °C kW) | 22,4 - 127,3 | 25,7 - 148,7 |

| Nominal Heat Power (80/60 °C kW) | 20,6 - 112,4 | 22,9 - 134,7 |

On the contrary to many other companies, each device manufactured by GRON goes through not only safety tests but also efficiency and emission tests through laboratory equipment. Therefore, attention is paid to being economic and environmentally friendly in addition to maximum safety.

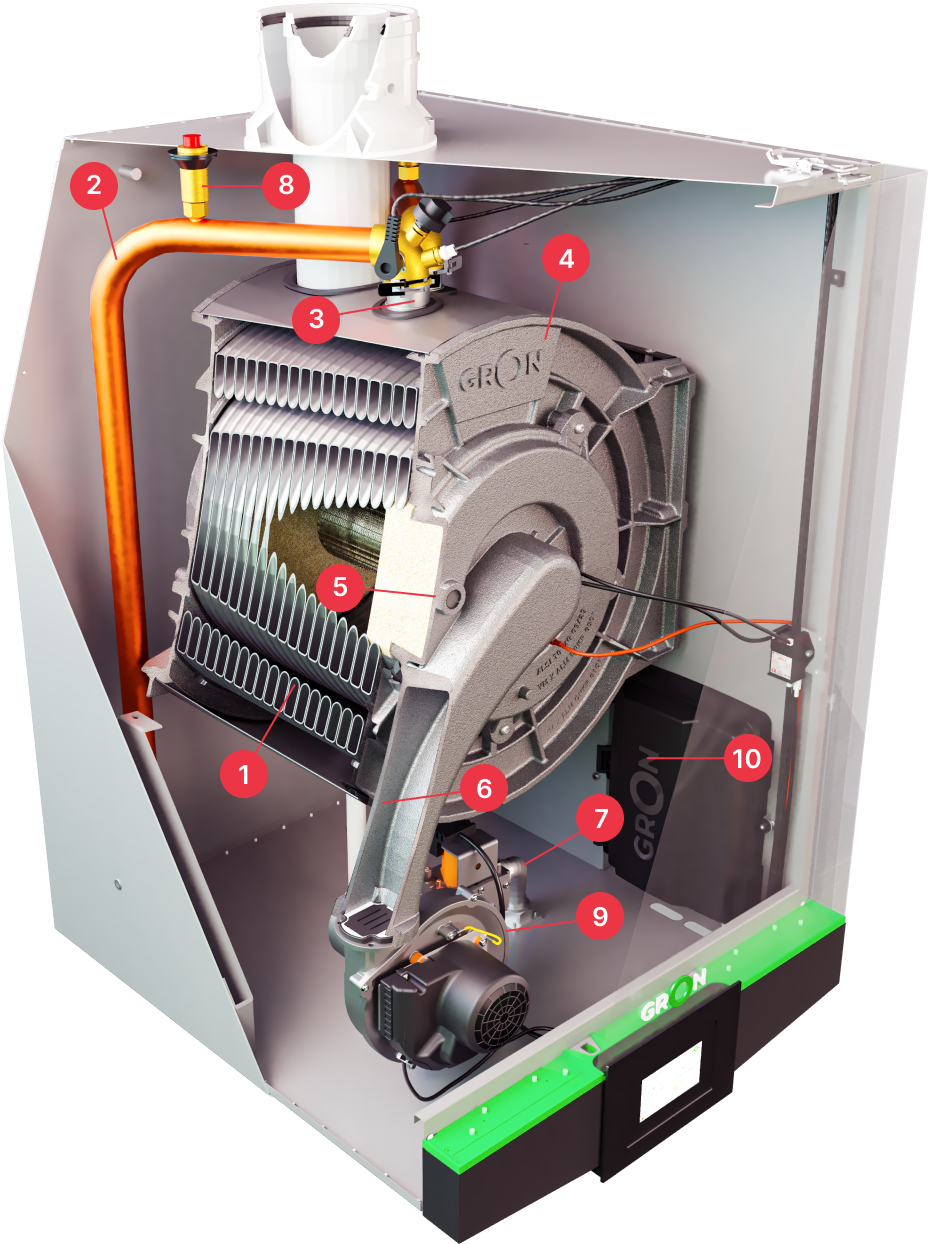

The highest quality components are preferred in the product design for long term comfort.

1 Despite its higher costs, 1.5 mm wall thickness stainless material is used instead of 0.7 mm in the profile bunches inside the exchanger.

2 A copper pipe is used instead of iron or galvanized pipes in the entire water piping inside the device for a longer service life. Moreover, the copper pipe is 35 mm in diameter, not 28 mm, for a longer service life for the exchanger.

3 The o-ring quick connect method is used in the exchanger inlets and outlets for a longer service life and tightness at connection points.

4 Special design, heavy cast body aluminum front and rear covers are used, ignoring the increased costs, therefore, maximum heat absorption and distribution is obtained, leading to a longer service life. (Page 8)

5 Again sparing no costs, the German made 75 mm Vermeculit (insulation material) is preferred for heat insulation in the combustion chamber. It increases efficiency while minimizing heat loss.

6 Despite the high costs, a long channel which the gas-air mixture goes through after the fan is created in the cover design. With this channel, the heat generated on the combustion chamber surface is transferred to the gas-air mixture into the appliance. This increases the device efficiency while minimizing the heat loss. (Page 7).

7 A 28 mm stainless flex pipe is preferred in the gas connection instead of cost cutting methods such as iron or copper pipes.

8 In order for the appliance to operate healthily for a long time, 2 cap Flamco air relief cocks are used on both the cold and the hot water lines.

9 German Ebm brand is preferred for the fan, gas valve and venturi group on the product.

10 German Siemens brand is used on the control panel and board on the product.

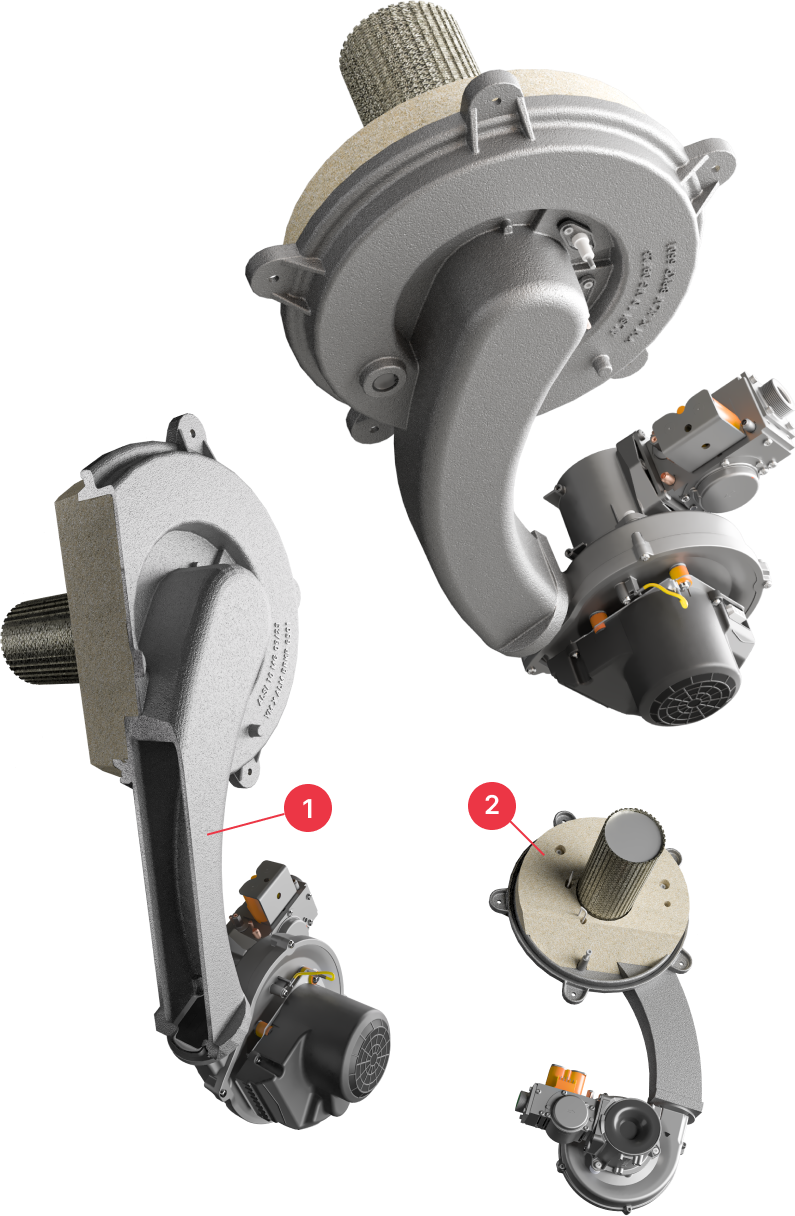

High heat loss is experienced outside the combustion chamber during operation on standard devices.

1 Despite its high cost, a long channel which the gas-air mixture goes through after the fan is created in the cover design. With this channel, the heat generated on the combustion chamber surface is transferred to the gas-air mixture into the device. This increases efficiency while minimizing heat loss.

2 Despite its high costs, a special 75 mm German made Vermeculite (insulation material) processed on CNC machinery is used inside the cover to increase efficiency by minimizing heat loss.

Wall mounted stainless exchanger approved by Internationally Accredited Laboratories.

A Patented original exchanger design.

1 Despite being a challenging method of manufacturing, a double helix profile structure is preferred instead of a single helix design, increasing efficiency and prolonging the service life.

Despite its higher costs, 1.5 mm wall thickness stainless material is used instead of 0.7 mm in the profile bunches inside the exchanger.

2 Despite its higher costs, the front and rear walls of the exchanger are made of cast aluminum material for long term robustness and customer satisfaction. Thus, the product heat is evenly distributed onto the surfaces, leading to a longer service life and better efficiency.

GRON engineers gave priority to durability, high efficiency and quality while designing the product. Yet, possible errors in product mounting and installation can reduce efficiency while shortening the service life. Our engineers designed an original practical mounting kit for the respective parts to prevent possible errors, apart from many other manufacturers.

1 It is easier and healthier to mount the product thanks to the original demountable stand design by our engineers.

2 Thanks to the collector piping kit supplied depending on the cascade structure you need, inefficiency due to wrong piping calculations and wrong installations are prevented. Moreover, thanks to its demountable structure, the system piping is very practical. Furthermore, we supply the equipment on the installation from companies which are tested in our laboratories.

3 The device’s practical and accurate sub piping group is supplied by our company. Therefore, it shortens mounting times and offers a healthier installation structure.

GRON company’s quality personnel track every product with its serial number. Our products are put in special packages which are tested by our company to minimize possible damages during delivery. In this design, for easy and healthy delivery despite its higher costs, every product is shipped inside Styrofoam cases with a wooden pallet at the bottom.